Hot-melt pistols

If you use hot-melt pistols regularly, you have certainly encountered the problem: which type is the best. Why would you pay 20-40 EURs more for a pistol? Are the cheap ones good ones at the same time?

UNIOTECH Pocket guide tries to find the answer to this question

Firstly, let us see the most important question: what the cheap ones are good for? Let us enclose a picture with no regards to the type marking.

These instruments have been developed for home use, for hobby purposes. Their lifespan ranges from 2 to 3 years, if using them for 20-30 minutes at a time, once or twice a month. They are absolutely inconvenient for industrial use.

Of course, this is not marked on their packaging. And really, lots of important information is missing from the packaging of these products.

No minimal melting capacity is written. This should be marked in g/min or kg/hour. Without this data, how could we plan production speed?

What else is missing? They are not equipped with spring stop valve for preventing dripping. So, obviously the melted material is continuously released at the front of the device.

No temperature regulator. The solution of this problem is that these devices work with a maximum performance of 15-40W (in case it is a performance at all). Low performance is also the solution against run hot even after 30 minutes of operation, although when we feed the bond, we can access a phase when the inserted rod cools down the pistol and we have to wait until it reaches the operating temperature again. Another feature of these products is the 10-15 minutes’ warm-up period and after 1-2 hours of operation, the widely- known and frequent event when the product stops working after a little bit of smoke and light effect. (as in case of most electrical equipment, it is also true here that the product releases smoke when in operation and when the smoke is over, the product is not working any more either).

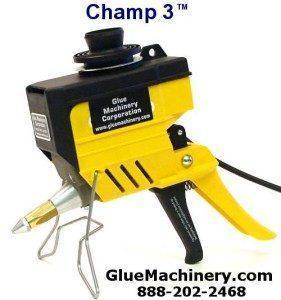

What is a good quality pistol like? This photo is only an illustration, lots of other good quality products are available on the market.

Features of a good device:

It has integrated spring stop-valve to prevent dripping (in case of proper handling this feature works permanently)

It has integrated thermal relay, so its performance ranges between 20-30/150-200W. It can be seen that the performance of these devices at temperature maintenance stage is larger than the total performance of low quality products. Like this, the time until we can first use the product can be reduced to 1 minute. There are cases when maximum temperature is also adjustable.

On the datasheet of the product we are informed about the maximum melting capacity (e.g. the device in the picture is able to melt as much as 1400g/hour).

1-2 year of guarantee is supplied even in case of industrial use.

Some spare parts are available.

These are the main differences between the pistols operating with 12mm plastic rod. Hopefully this information provides you with some help when you are intended to buy hot-melt pistols.

A good selection of the appropriate device can save you much annoyance and money.

Last, but not least we would like to mention some top choices, although we do not want to write about them in details as in this field you are not offered bad quality, low capacity ones.

These hot-melt pistols are operating by using granules, their top capacity is 4-800W and they are used for hot-melting large surfaces.

They are the choice if you have to stick together lots of large surfaces instead of lots of small ones